What Are NEXGEN Doors?

NEXGEN doors are cost-effective and durable cabinet doors made with heat-, scratch-, and fade-resistant materials in a variety of colours.

Over the past four years, the cost of cabinet doors has increased dramatically, with some products (like Rift Cut White Oak) more than doubling in cost. As a result, prefinished materials like thermofoil and NEXGEN doors are more popular.

When unfinished cabinet doors for an average-sized kitchen (about 40 doors and drawer fronts) cost at least $1500, you may feel justifiably alarmed about how much a new kitchen or a kitchen renovation will cost.

What if you can’t afford that? Are there any cost-effective cabinet door options available to you?

Here’s where NEXGEN™ doors come in. At Cutting Edge, we have sold NEXGEN cabinet doors for over six years. Over that time, we discovered that NEXGEN doors are a highly durable, practical, and inexpensive cabinet door option.

In this article, you will learn:

Introduction to NEXGEN cabinet doors

NEXGEN™ are polyester-wrapped MDF products, specifically components used for cabinet doors. It is not a manufacturer, but rather an actual product that was trademarked by Olon Industries, Inc in 2016. Here at Cutting Edge, we use NEXGEN products to provide our customers with a high-quality yet affordable option for their cabinetry needs.

NEXGEN doors are a pre-finished product

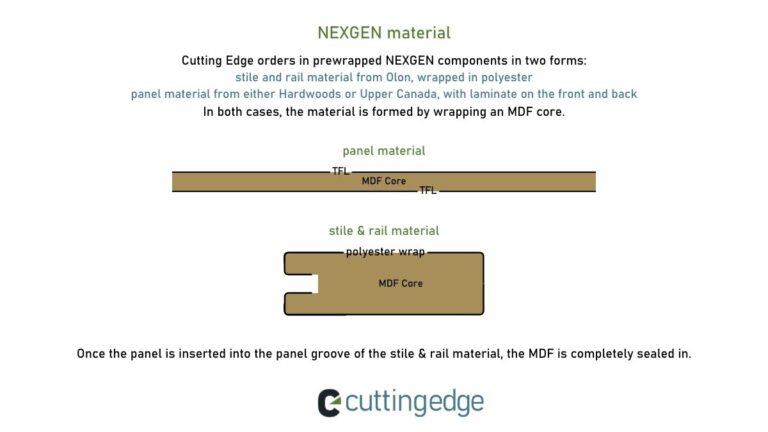

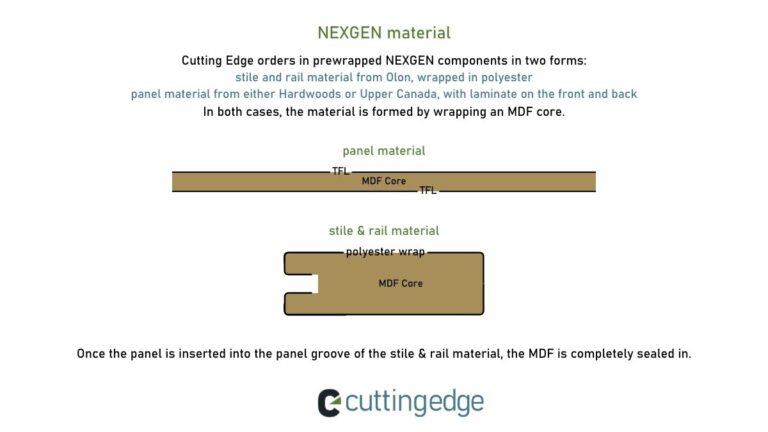

The components that comprise NEXGEN doors are made of MDF (medium-density fibreboard). The stiles and rails are wrapped in polyester, and the panels have TFL (thermally-fused laminate) on the front and back.

The MDF core serves as a stable base and keeps the cost of the NEXGEN components low. Also, the shape of the MDF core provides the design for the doors. For example, the MDF core is left square for a shaker style NEXGEN door. On the other hand, the MDF core has a chamfer inside profile when you order a chamfered NEXGEN door.

Honestly, though, most of the work of a NEXGEN door is done by the polyester and laminate wrap. The wrap serves four purposes:

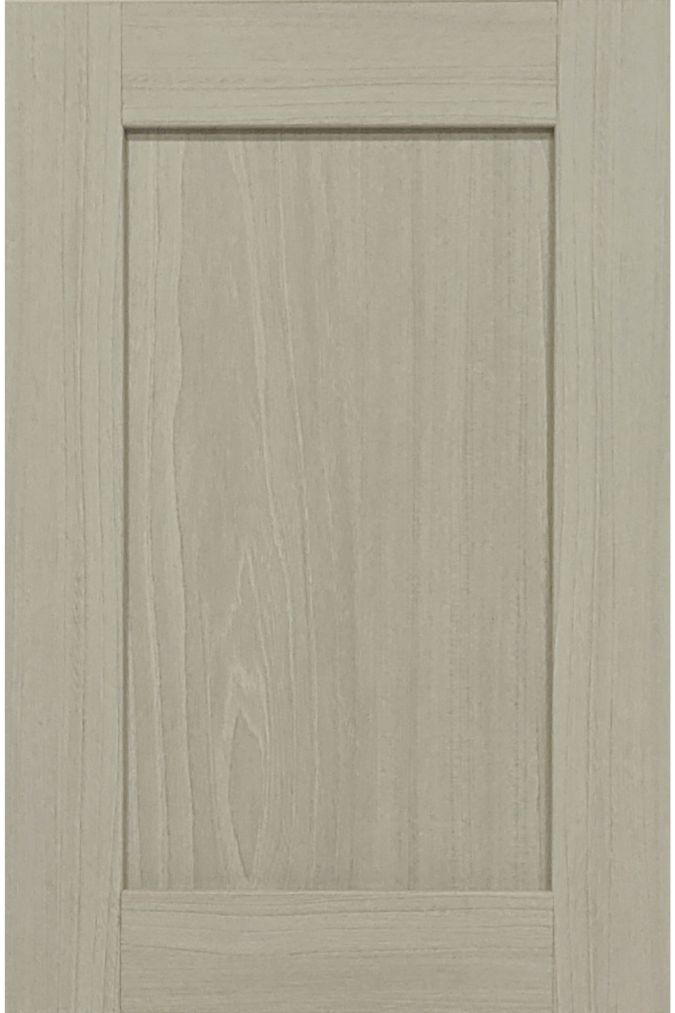

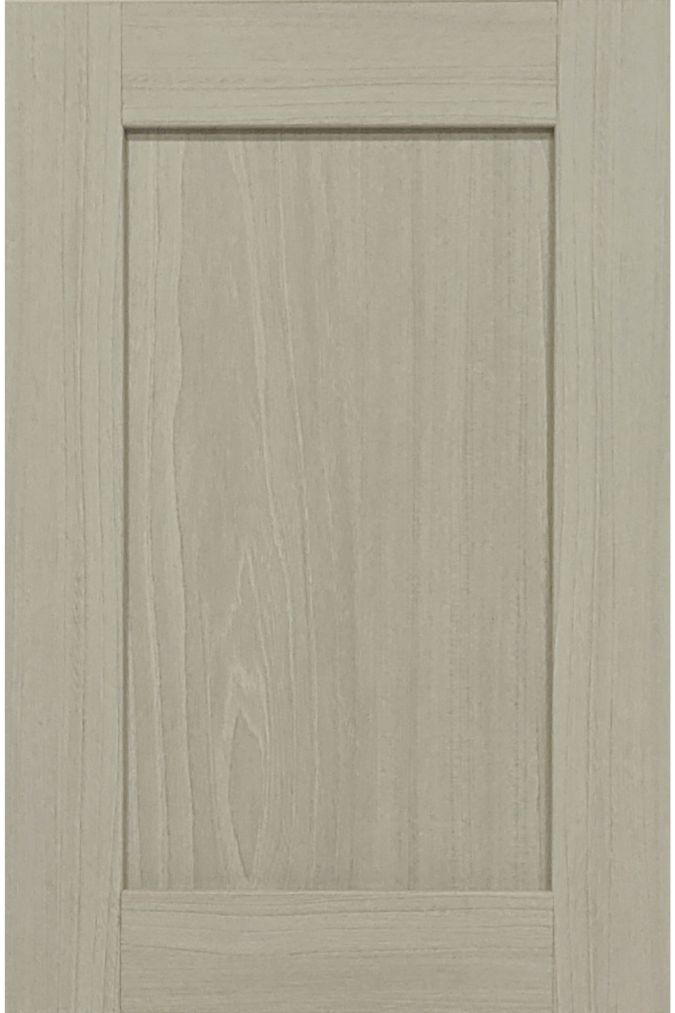

1. Makes the NEXGEN door look like a wood door

You can choose from a wide variety of wraps. Some wraps are solid colours, others are textured and patterned to look like wood, and others are textured and patterned to look like other products, concrete or stone, for example.

2. Reduces the MDF formaldehyde emissions

One of the main drawbacks of MDF is that the manufacturers use a formaldehyde-based glue to bond the wood composite that makes up MDF. In high quantities, formaldehyde can irritate the nose, throat, and eyes and increase the risk of cancer.

While MDF itself does not emit enough formaldehyde to be a concern (all the MDF products we sell are TSCA Article 6 Certified), the wrap around the MDF core of NEXGEN cabinet doors reduces the formaldehyde emissions to almost zero.

3. Makes the NEXGEN door very durable and easy to clean

The polyester wrap and the TFL used for NEXGEN products have built-in anti-microbial protection, which helps kill or slow bacteria, viruses, and fungi like mould. In addition, the polyester wrap and the laminate are scratch- and heat-resistant. These three attributes together make NEXGEN cabinet doors a great choice for high-use environments.

But those aren’t the only benefits. The wrap is also fade-resistant, unlike wood products, most laminates, and thermofoil coatings currently available. As most products are exposed to sunlight, cleaners, and everyday use, they fade or change colour. However, NEXGEN’s fade-resistance means that if you need to add additional doors years from now, your new door will match the current doors exactly.

Also, the wrap is very easy to clean. Just wipe it down with a damp cloth and ordinary soap. If needed, you can even use general-purpose cleaners on NEXGEN cabinet doors.

4. Keeps the cost down

Of all the benefits you have learned about so far, the main benefit to the wrap is that it keeps the cost down.

Your supplier does not need to stain, paint, lacquer, or sand NEXGEN doors. They require little labour; your supplier only needs to cut the components to the correct size, assemble the door, clean off any residues or dust, and pack the door up for shipping.

How Cutting Edge builds NEXGEN doors

At Cutting Edge, we have two methods for building NEXGEN doors: cope and stick assembly and mitred assembly. Both assembly methods use two types of NEXGEN components: stile and rail material provided by Olon Industries and panel material provided by either Hardwoods or Upper Canada, depending on the material type you choose.

Cope and stick assembly

Cope and stick assembly is becoming more popular because it more closely resembles traditional shaker-style cabinet doors.

With the cope and stick assembly method, we cut the stile and rail material into four pieces: two rails and two stiles. The rails are tennoned (or shaped) to fit around and inside the stiles.

Next, we cut the centre panel from the panel material.

Then, we assemble the two stiles, two rails, and the centre panel and add glue at each of the four joints to hold the door together.

Once we have built the door and the glue has set, we add matching edge tape around the four exterior edges. The edge tape has two purposes:

- It hides the raw MDF that the cope and stick method exposes at the ends of the stiles.

- It adds extra stability.

A cope and stick NEXGEN door is weaker than a mitred NEXGEN door because the cope and stick joint has a limited surface area for the glue to adhere to.

Mitred assembly

Our team recommends mitred NEXGEN doors because they are more stable and less expensive.

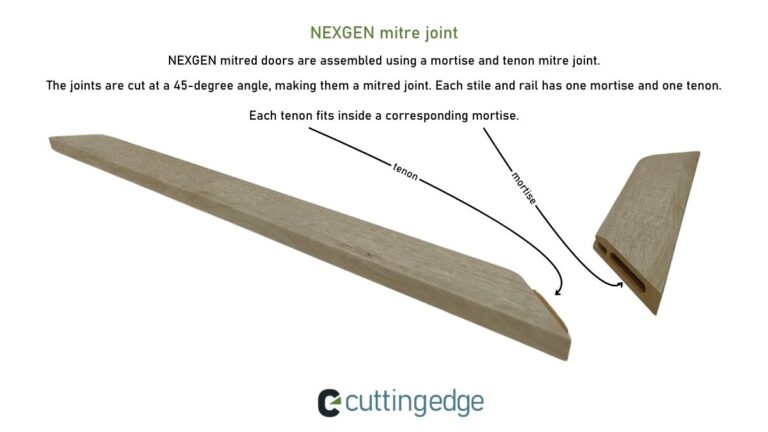

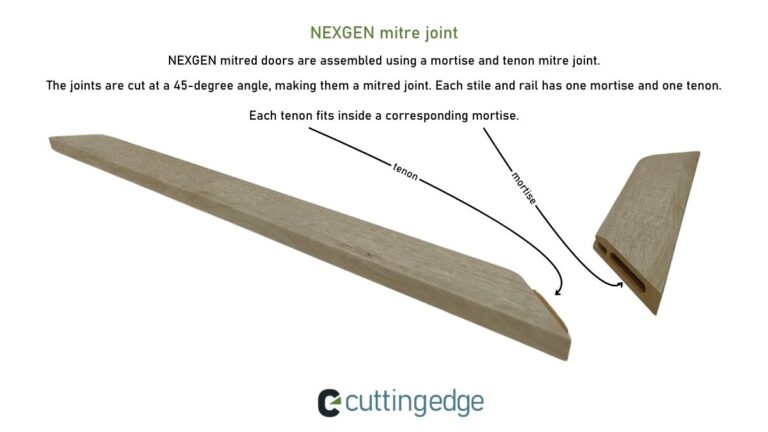

Like cope and stick NEXGEN doors, mitred NEXGEN doors also have two stiles, two rails, and a centre panel. However, instead of using a cope and stick joint method, we use a mitred mortise and tenon joint.

The mitred joint provides extra stability because the mortise and tenon have more surface area for the glue to adhere to.

Also, mitred NEXGEN cabinet doors do not require edge tape because the assembly method does not expose raw MDF. Instead, it leaves the polyester wrap intact around the entire door.

Common uses for NEXGEN cabinet doors

NEXGEN doors are, as you have already learned, cost-effective, durable, and easy to clean. These three attributes make NEXGEN cabinet doors an excellent choice for high-wear, high-use environments like rental homes, apartments, and other commercial buildings.

In addition, the built-in anti-microbial protection and reduced formaldehyde emissions mean you can use NEXGEN products in health-conscious environments like healthcare facilities and schools.

NEXGEN doors are a cost-effective and durable option

At the end of the day, we have all encountered budgeting difficulties and cost concerns when it comes to cabinet doors. This is especially true if you are working on a large project with a low budget for cabinet doors.

Now that you have learned from Cutting Edge Doors & Woodworking why NEXGEN doors are a cost-effective option for high-wear environments, it’s time for you to contact us to learn more about NEXGEN.